“Lettuce” Explain Why Stainless-Steel Construction Isn’t Always a Washdown RequirementAlba Manufacturing2023-12-13T15:45:06-05:00

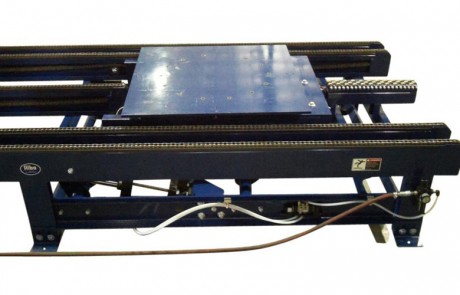

Alba Answers the Demand for Superior Cold Storage PerformanceAlba Manufacturing2022-11-19T20:34:14-05:00

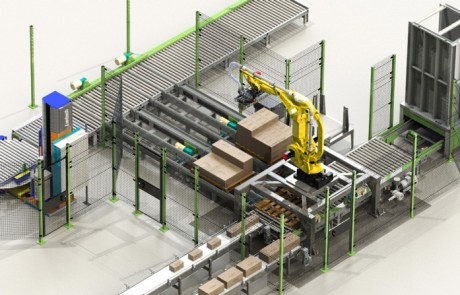

Increased Demand for Fizz Leads to a New Robotic Pallet Conveyance SolutionAlba Manufacturing2021-10-19T18:50:05-04:00

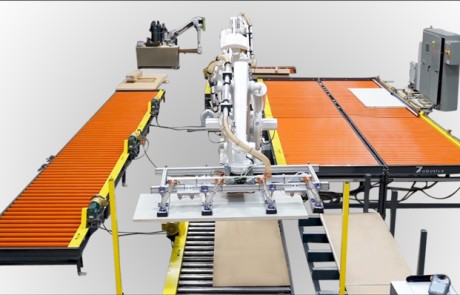

Scrubbing the Inefficiencies Out of Appliance ManufacturingAlba Manufacturing2020-12-17T14:43:14-05:00

When You Manufacture the Very Best, You Use the Very BestAlba Manufacturing2020-09-03T08:42:01-04:00

Conveyor Trifecta: Flexible, Dependable with Substantial Cost SavingsAlba Manufacturing2020-09-03T09:03:53-04:00