Problem

A large food product manufacturer faced the challenge of handling expanding production volumes. The product (stacked cube loads with slip sheets) needed to be moved from the packaging equipment area in the production building over to a stretch wrapper in the warehouse building. Part of the challenge – to cross over high traffic aisle ways safely and still allow fork trucks and personnel through the area all while meeting the increased production cycle times.

Solution

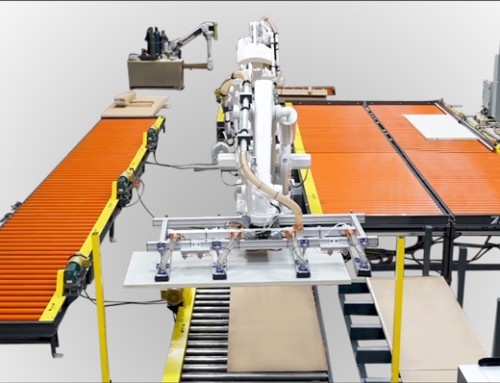

Alba’s sales team met with the customer’s engineering group. They determined the best solution was to utilize Alba’s standard transfer car (t-car) technology and to add safety devices allowing safe operation through the high traffic area. In addition to the transfer car, the system contained chain driven live roller (CDLR) and transfer conveyors.

Results

In addition to the t-car, Alba also provided the ability to convey product from one of three packaging lines to a main transportation line. The main conveyor line fed the t-car which took the unwrapped product from Building #1 (production) to Building #2 (warehouse). Once the product was in Building #2, it traveled down the line to one of two stretch wrappers for wrapping. After product wrapping, the loads were conveyed to central pick up stations where fork truck operators scanned the loads and transported them to warehouse storage until the product was shipped to the end user.

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.