Problem

One of our partners, an integrator, needed a durable, long-lasting solution to bi-directionally strap pallet loads within their system. The end-user needed a sturdy and reliable piece of equipment that could take the added weight of their compression head which added 2,500 lbs. to the existing 4,000 lbs. pallet for a total weight of 6,500 lbs.

Solution

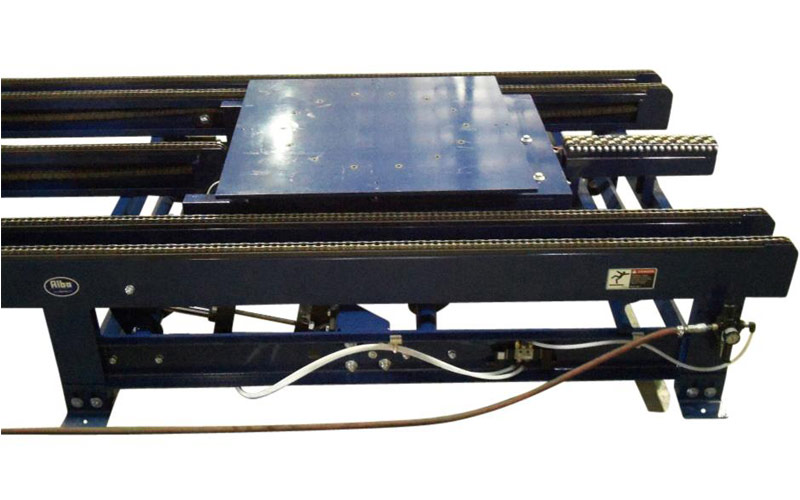

We combined our pre-engineered drag chain conveyor with a lift and rotate device to convey a pallet into a strapping zone wide-way leading to strap a full pallet in one direction. Next, we changed the pallet direction and transported it back into the strapping zone a second time to be strapped in the cross-direction.

During the initial strapping, the pallet is supported by five chains. After a 90 degree rotation (narrow-edge leading) the pallet is supported by three chains. Alba accomplished this with a special 5-strand drag chain conveyor that was integrated with a lift and rotate device. Our unit easily handled 6,500 lbs. pallets (4,000 lbs. pallet load plus a 2,500 lbs. compression head).

Using a strong design incorporating flat side bar chain, Nylatron wear strips and a heavy duty lift and rotate turning plate, Alba provided a unit that met the requirements and would last for years to come. For more information about our lift and rotate device, click here.

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.