|

In the custom door manufacturing industry, speed, precision, and flexibility are everything. Products range from single solid wood doors to towering stacks, all demanding delicate handling despite their weight and size. When one manufacturer sought a turnkey solution to automate and accelerate this process, they found their answer through a powerful partnership: 7robotics and Alba Manufacturing.

The Challenge: Speed, Variety, and Seamless Integration |

|

Based in Roseburg, Oregon, 7robotics is a member of the Alba Partner Network (APN) and a recognized expert in robotic automation—especially for handling wood-based products like doors, veneers, and plywood. Their unique name is derived from three things: there are seven axes to a robot, the number seven in the Bible (appearing over 700 times) symbolizing completion or perfection, and lucky number seven.

7robotics’ latest project required a complete automation system that could handle both individual doors and stacks measuring up to 48" wide by 120" long and weighing as much as 4,400 lb. per stack. The solution also had to seamlessly integrate with an edge-bander and accommodate a wide range of door sizes.

While the end user initially explored an option from the edge-bander supplier, they were met with steep costs and extended lead times. That’s when 7robotics stepped in. Known for fast, creative problem-solving and out-of-the-box thinking, they took on the challenge—and turned to Alba Manufacturing to help deliver.

The Solution: Custom Conveyors with a Critical Edge |

|

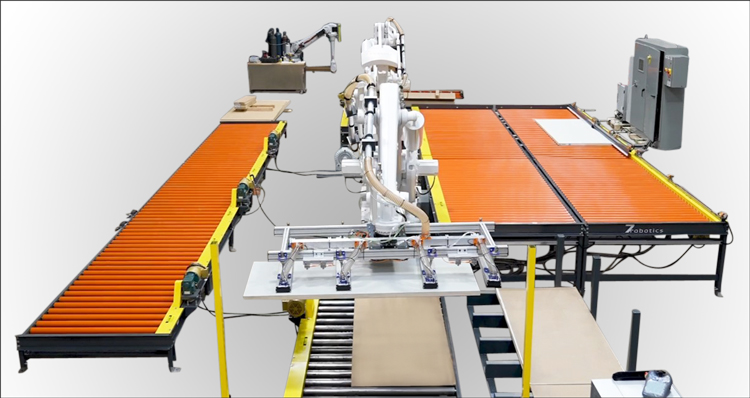

7robotics needed more than just conveyors—they needed a material handling system tough enough to handle oversized stacks yet gentle enough for individual wood doors. Alba Manufacturing delivered.

At the core of the system was a series of Chain Driven Live Roller (CDLR) conveyors. As part of the solution, Alba customized them with 1/8″ thick Kastalon-coated tubes to protect doors from scratches, dents, or any other damage during transport. For other parts of the process, standard CDLRs without coating were provided.

To facilitate efficient and accurate movement between sections, Alba also supplied two types of frame-to-frame transfers: one with seven v-belts and another with three v-belts. These critical components ensured doors were properly aligned and transferred seamlessly for edge-banding.

Better still, all conveyors and transfers were shipped fully assembled—Alba’s standard practice—allowing 7robotics to expedite robotic cell testing and fine-tuning.

The Result: A Turnkey System That Raises the Bar |

|

Thanks to the collaboration between 7robotics and Alba, the end user now benefits from a fully automated feeding and stacking system that handles a broad spectrum of door sizes and weights with ease.

The Kastalon-coated rollers safeguard each door during movement. The frame-to-frame transfers precisely align every piece. And the entire system runs at the speed required to meet tight production demands—all without compromising quality or safety.

This solution proves what’s possible when forward-thinking integrators like 7robotics work hand-in-hand with trusted manufacturing partners like Alba. Together, they created more than a system—they created a standard for innovation in the custom door industry.

Alba Manufacturing is your full-service, conveyor manufacturer for all your pallet handling applications. Call us to locate your nearest Alba Partner Network Member today via email at rocksolidconveyor@albamfg.com, telephone at 866.252.2634 or visit our website at www.albamfg.com to discuss.

Conveyor/Product Specifications |

|

|