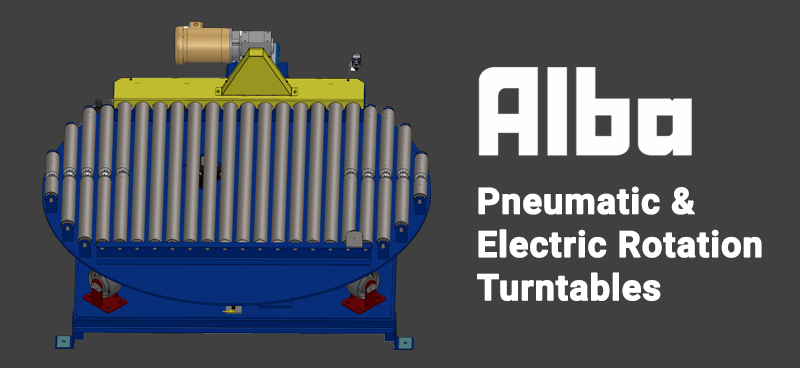

Behind the Rollers – Alba's Pneumatic & Electric Rotation Turntables |

|

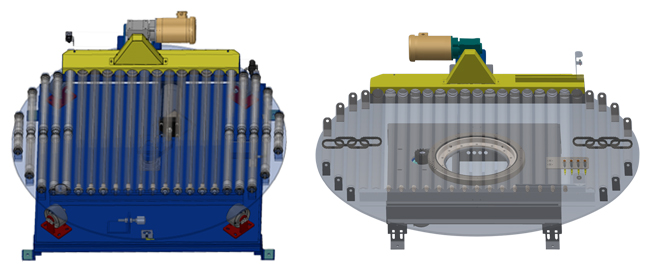

Alba’s powered rotating turntables are a critical component of a pallet handling conveyor system when the pallet’s leading edge must be maintained during a directional change. The turntable’s mounted conveyor design allows every roller to be driven, providing positive drive to the pallet until the pallet is fully conveyed from the turntable. Alba’s turntables can be split into two main subgroups based on the method of rotation. The electric version uses a 1HP gearmotor with brake to drive rotation, while the pneumatic version drives rotation with a large air cylinder.

At first glance these turntables appear very similar, but after a closer look, the differences become more apparent. Identifying differences between the designs and when to utilize each type is the focus of this month’s AlbaGram; where we go BEHIND the ROLLERS to examine Alba’s conveyor mounted electric and pneumatic turntables.

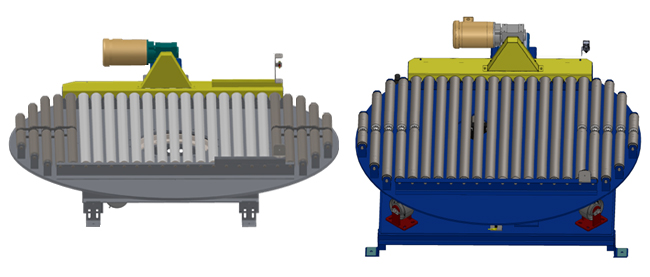

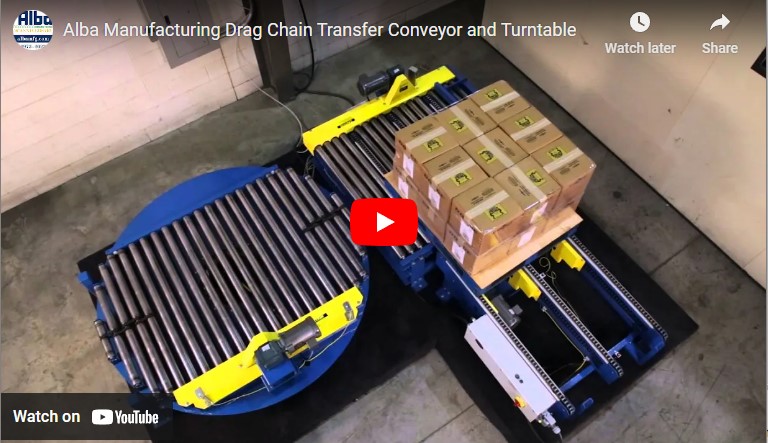

There are two primary ways to change a pallet’s direction in a conveyor system. The first is a pop-up chain transfer as discussed in the previous Behind the Rollers installment. The transfer will keep the pallet’s same spatial position but will change it’s leading edge. The second way is the conveyor-mounted turntable. The turntable’s advantage is that it allows the pallet to maintain its leading edge throughout the directional change. Maintaining the pallet’s leading edge is important in pallet strapping applications, when scanning a bar code or license plate is needed, or when bottom board orientation needs to be maintained for downstream handling purposes.

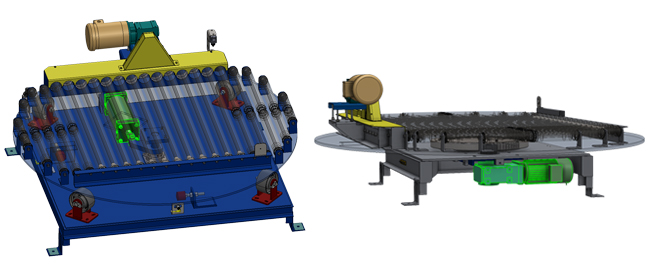

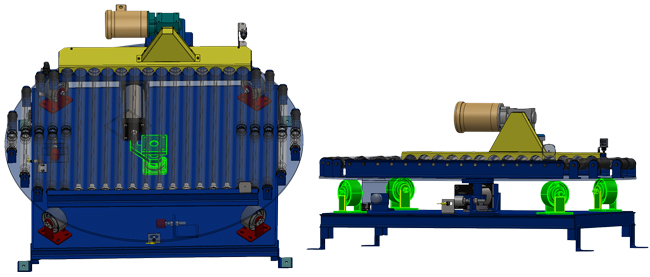

Deciding the best method of rotation for the application tends to diverge in the following ways, electric rotation is better suited for heavier weights with faster cycle times, if the application requires rotating beyond 90°, or if pneumatics aren’t available in a certain area or environment such as a freezer. Pneumatic rotation on the other hand is generally a more cost-effective solution when 90° or less of rotation is all that is necessary. The differences in components between these two units can most clearly be seen when you are able to look below the rollers.

Rotational Drive |

|

The pneumatic rotation turntable uses a pneumatic cylinder which enables the rotation. Adjustable rubber bumper positive stops and an air flow control valve allow the rotational alignment and speed to be dialed in during installation. The electric rotation version turntable uses a VFD-rated gearmotor with brake which when coupled with a customer supplied control system, allows the rotation to be much more controllable for soft starts and stops. The electrical rotation unit also allows for the inclusion of an optional slip ring, permitting the turntable to rotate beyond 180° and continuously should the application warrant it. This allows all power and control wires mounted to the top plate to be terminated to the slip ring for rotation free from binding wires.

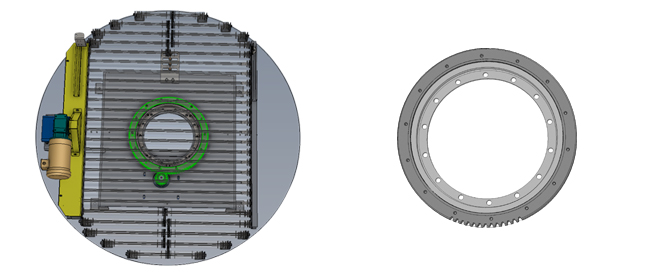

Rotational Bearings |

|

One of the most critical mechanical components necessary for a reliable turntable operation is the bearings. The pneumatic turntable uses a reliable combination of a central flange bearing and an array of casters to support the perimeter of the turntable disk plate. The electric turntable, alternatively, uses a heavy-duty slewing ring bearing, typically seen in heavy duty equipment (i.e. tank turrets and heavy duty construction equipment). This slewing bearing has a grease manifold allowing grease to be applied to the bearing for easy maintenance from a common point at the edge of the turntable base.

Alba has been integrating industry-leading turntables into pallet handling applications for over 50 years. Have an application? Collect all the pertinent product information and general application requirements and let us work with you to develop a solution.

For additional information on pallet turntable conveyors and other pallet handling equipment, reach out to our Sales Team today! For rock-solid solutions and conveyor systems, contact Alba Manufacturing today at at 866.252.2634 or visit our website at www.albamfg.com to discuss. |