Alba Meets the Challenge with a Micro-Lifting Conveyor |

|

How many times have you encountered a situation in which elevations did not align? Possibly you had a lower elevation entering a conveyor system (such as a turntable or transfer) that needed to be raised to meet the design specifications? Or maybe your new conveyor line did not align with your existing line at the same elevation?

Traditionally, scissor lifts have been used to change the elevation of a conveyor line when these challenges arise. That makes sense when the elevation difference is measured in feet instead of inches. But what do you do when you only need a few inches to make up the elevation difference? Does a $6,000 to $8,000 scissor lift still make sense for this small change in height? Well, at least, it might not make financial sense for your project budget.

One might say, why not use an incline or a decline of the conveyor to change the elevation? This is fine in a relatively light weight case or carton conveyor application; however, when conveying heavy weight pallets, these slopes can present other issues. First, elevating the conveyor's angle necessitates a higher horsepower demand. Second, attention must be paid to the smooth transition of pallets as they move from the sloped section back to the level conveyor, especially at the incline or decline endpoints. The pallet wants to "nosedive" at that location between rollers and can get stuck causing a logistical problem where maintenance personnel will have to clear the jam.

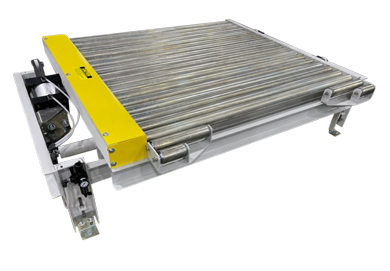

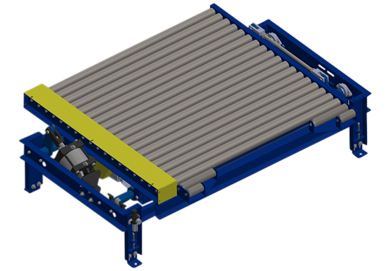

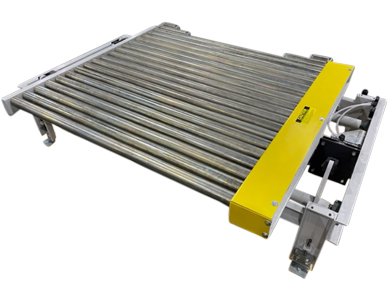

While scissor lifts can be expensive, increase cycle time, be harder to maintain and require another motor controller in your control package, they may not be the right fit for the application. Additional sloping the conveyor could lead to horsepower or transitional issues for the pallet which is not a good option either. Alba has an answer for all these challenges. Alba introduces a conveyor top that has a lifting base capable of four inches or less of elevation change.

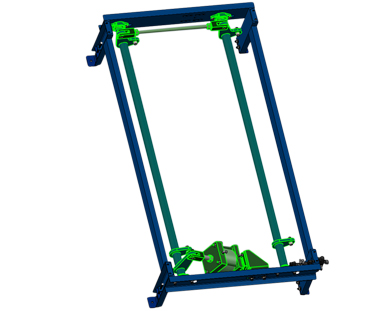

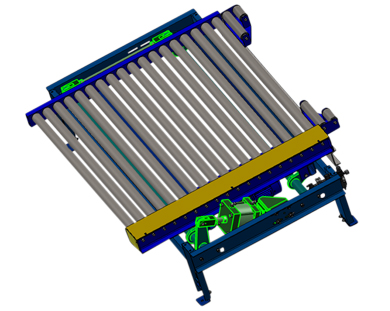

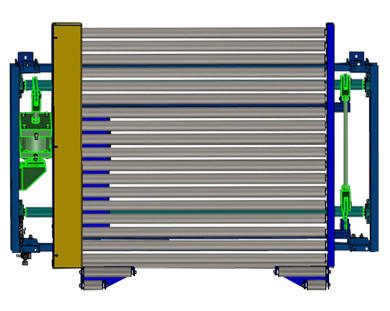

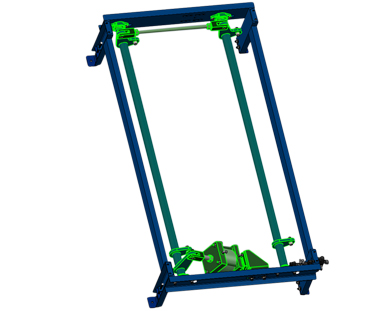

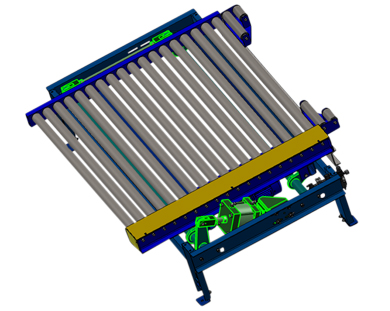

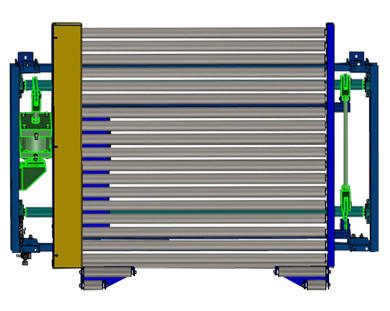

This conveyor top can be a CDLR conveyor or a drag chain conveyor or even a gravity conveyor top. This design utilizes a standard conveyor such as the above CDLR conveyor and then adds a lifting base to it so that it can articulate up and down to meet a change in elevation of up to 4”. The base incorporates Alba’s standard, robust, 4-point positive lifting mechanism which is the same design that is used in Alba’s pop-up chain transfer conveyors.

| |

|

|

|

|

|

The lifting is accomplished by an air cylinder as opposed to that of a messy hydraulic pump and motor as in most scissor lifts. The two (2) pivot rollers with cam arms allow lifting in unison when coupled together with the included tie-rod and cylinder. The lifting base comes complete with a standard 24 VDC double solenoid valve with speed control mufflers pre-piped to the cylinder with poly tubing and the proper air fittings and can include an optional filter-regulator with gauge. The result is quiet, smooth, and rapid lifting and lowering to meet the needs of your small elevation change.

Why is this design a good idea for your project? Simply put...Reliability and Price! The lifting base design is a proven workhorse in the field and the price is thousands of dollars less than a traditional scissor lift base design.

For additional information on our micro-lifting conveyors or other pallet handling equipment, please reach out to our Sales Team today! For rock-solid solutions and conveyor systems, contact Alba Manufacturing today via email at rocksolidconveyor@albamfg.com, telephone at 866.252.2634 or visit our website at www.albamfg.com to discuss. |