|

When it comes to freezer-rated pallet conveyor systems, not all designs are created equal. Many of our network partners approach us with preconceived ideas about what works best—or they rely on Alba’s decades of experience to guide them toward the most reliable solution for these demanding environments.

At Alba Manufacturing, we engineer heavy-duty conveyor equipment built to perform in freezer conditions as low as -20°F. Through years of field testing and real-world application, we’ve refined our approach to ensure consistent operation where many systems fail.

That experience often leads to one key question from customers and integrators:

"Why does Alba use hydraulic cylinders and power units instead of electric cylinders to raise and lower 90° pop-up chain transfers?"

It’s a fair question—and one worth exploring. While electric solutions may appear cleaner or simpler on paper, real-world performance in subzero environments tells a different story.

Many people also ask whether an all-electric solution could handle transfers, and blade stops inside the freezer instead of hydraulics.

The short answer: it’s technically possible — but not the best solution.

In earlier designs, Alba used motorized ball/acme screw units driven by electric motors to raise and lower transfers. However, years of field experience in freezer environments revealed recurring reliability and maintenance challenges that limited performance.

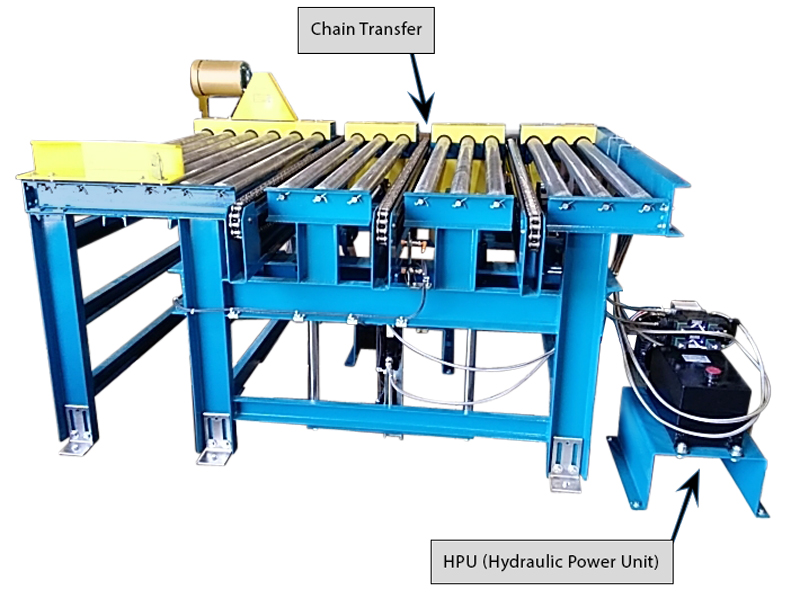

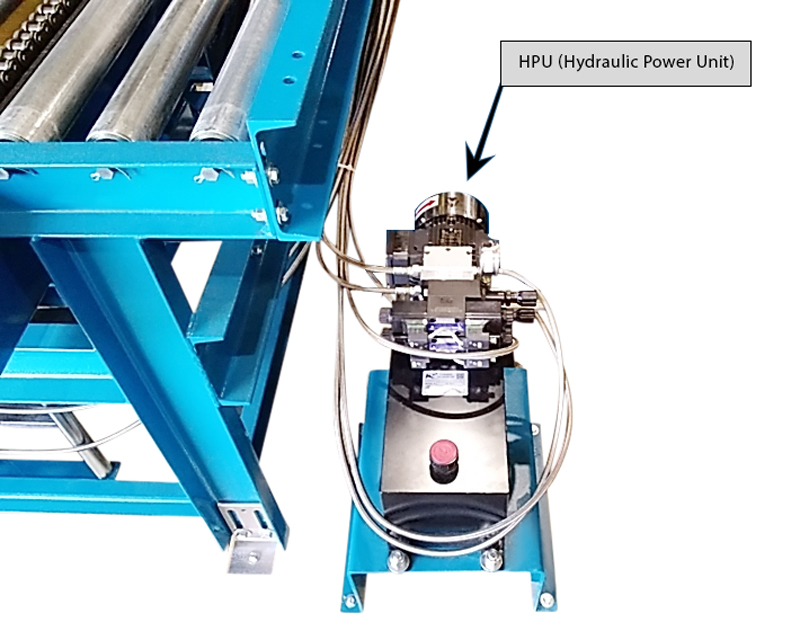

To overcome these issues, Alba transitioned to electro-hydraulic systems—using hydraulic cylinders powered by remotely mounted Hydraulic Power Units (HPUs). This configuration has consistently delivered superior reliability, speed, and efficiency in subzero applications.

Key Reasons for the Switch |

|

| • |

Proven Reliability: Hydraulic systems have provided superior long-term performance for more than 15 years, especially in demanding freezer applications. |

| • |

Continuous Design Improvement: The current configuration reflects years of engineering refinement based on real-world experience. |

| • |

Centralized Power with Remote HPUs: Remote-mounted HPUs simplify maintenance, improve system efficiency. |

Top 10 Reasons Hydraulic Systems Outperform Electric Actuators in Freezer Applications |

|

| 1. |

Efficiency and Speed |

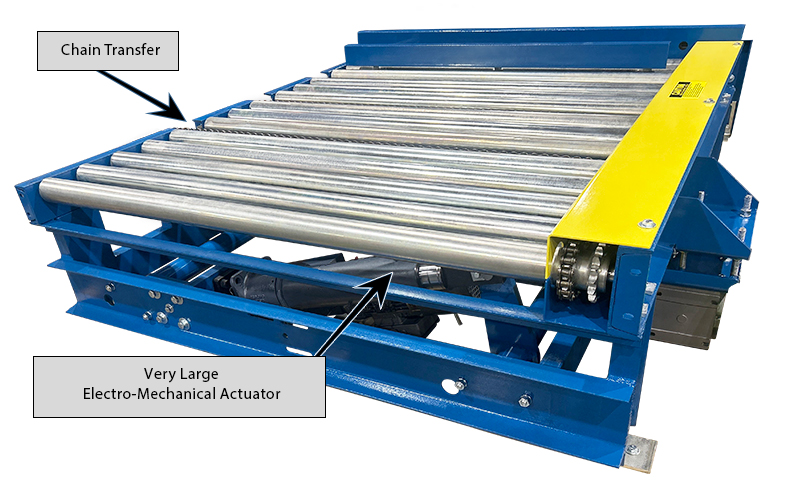

| Electro-mechanical units can take 15 seconds or more to complete a lift/lower cycle. They also risk shear pin failures if not precisely controlled. Hydraulic systems deliver faster, smoother, and more consistent motion. |

| 2. |

Mechanical Advantage |

| Hydraulics preserve Alba’s four-point positive lifting mechanism, ensuring balanced torque and a smooth, synchronized operation across the transfer. |

| 3. |

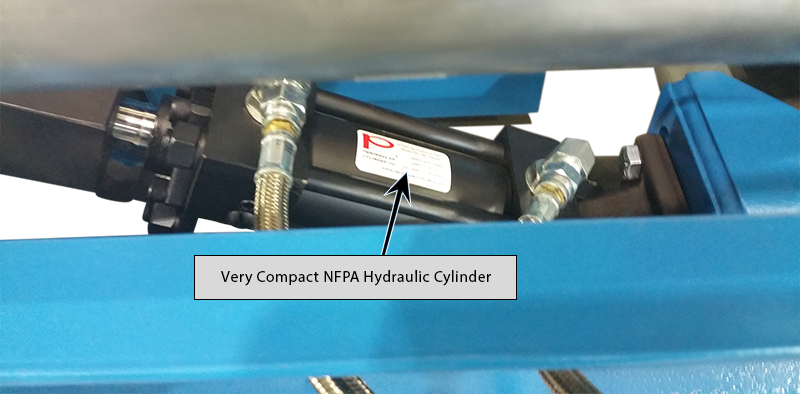

Compact Design |

| Hydraulic cylinders are shorter and less bulky than electric actuators, allowing for a lower-profile, space-saving transfer design. |

| 4. |

Failure Prevention |

| Electric actuators depend on over-travel sensors—any fault can cause damage or downtime. Hydraulic systems, powered by remote HPUs, provide reliable performance with fewer points of failure. |

| 5. |

Drop-In Compatibility |

| Alba’s NFPA-interchangeable hydraulic cylinders can be easily integrated into existing conveyor designs with minimal modification—offering cost-effectiveness and faster availability. |

| 6. |

Freezer-Rated Fluid System |

| Hydraulic Power Units (HPUs) use closed-loop circuits filled with freezer-rated (and optionally food-grade) hydraulic fluid, connected via two flexible eight-foot hoses. |

| 7. |

Leak Management |

| Optional drip pans beneath HPUs help contain fluid during maintenance, keeping operations clean and controlled. |

| 8. |

Proven Reliability |

| With more than 15 years of field success in subzero conditions, Alba’s hydraulic systems have a track record of uptime. |

| 9. |

Heavy-Duty Suitability |

| Freezer-rated environments demand rugged construction. Hydraulics provide the power and durability that electric cylinders can’t match in harsh conditions. |

| 10. |

Expandable Functionality |

| Each HPU can be configured to power multiple devices, such as pop-up blade stops—offering greater flexibility and scalability. |

Beyond Hydraulics: Other Freezer Considerations |

|

While hydraulics are at the heart of Alba’s freezer-rated transfer systems, that’s only part of the equation. Reliable performance in subzero environments requires every component—from rollers to sensors—to be engineered for cold conditions.

| Alba Manufacturing designs and supplies a complete range of freezer-rated components to ensure consistent operation and long-term durability throughout the entire conveyor system: |

|

| • |

Zinc-Plated Rollers and Axles |

| Corrosion-resistant and built for durability in low-temperature environments. |

| • |

Nylatron Wear Strips on Chain Rails

|

| Provide smooth, low-friction chain movement that withstands extreme cold. |

| • |

Freezer-Rated Motors and Gearmotors |

| Precisely engineered to deliver dependable torque and efficiency at subzero temperatures. |

| • |

Freezer-Rated Bearings |

| Maintain consistent performance and longevity despite cold-induced contraction and lubricant challenges. |

| • |

Freezer-Rated Sensors |

| Includes photo-eyes and proximity sensors calibrated for accuracy in freezing, moisture-prone conditions. |

| • |

Freezer-Rated Scissor Lifts |

| Engineered for stability and lifting precision in conveyor-mounted cold storage applications. |

| • |

Freezer-Rated Turntable Conveyors |

| Allow directional changes while preserving reliability in low-temperature environments. |

| • |

Adjustable Jack-Bolt Feet |

| Provide stable, adjustable support that accommodates uneven flooring. |

The Bottom Line |

|

In freezer-rated conveyor applications, success comes down to proven performance under pressure.

Alba’s electro-hydraulic systems have stood the test of time—delivering faster operation, greater reliability, and simplified maintenance where electric solutions often fall short.

But hydraulics are only part of the story. Every component in Alba’s freezer-rated line—from rollers and bearings to motors and sensors—is purpose-driven to perform in subzero environments, ensuring long-term dependability across the entire system.

When performance matters most, design experience makes all the difference.

If you’re evaluating freezer-rated conveyor options—or troubleshooting existing equipment, Alba’s engineering team can help identify the most reliable, cost-effective solution for your environment.

To learn more contact your Regional Sales Manager and locate the nearest Alba Partner Network Member in your area or telephone us at 866.252.2634 or visit our website at www.albamfg.com to discuss.

|