|

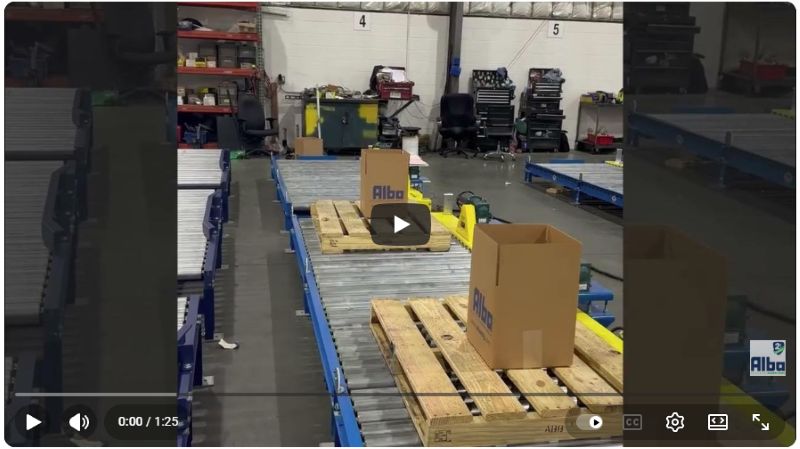

Alba Manufacturing recently worked with a long-time integrator partner to design a conveyor solution for a unique application. The customer needed a system that could move valuable palletized product from a secure cage through an automated roll-up door and stage them in the main warehouse for forklift pickup. The challenge was to create a solution that integrated seamlessly with the door’s operational controls while maintaining security, efficiency, and safety.

|

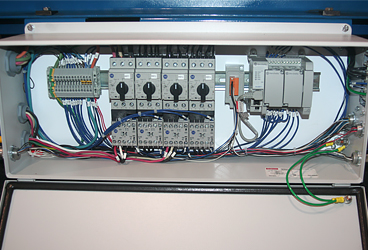

The system consisted of a six-zone Chain Driven Live Roller (CDLR) conveyor line, each zone powered by a 1/2 HP Baldor C-frame motor and Dodge Tigear II gear reducer. The conveyors operated at 30 feet per minute and were supported by heavy-duty supports, adjustable for precise elevation. To simplify installation and reduce complexity, Alba implemented its standard plug-and-play Motorized Zero Pressure Accumulation (MZPA) controls system, featuring an Allen Bradley Micro PLC and pre-installed programming. All wiring was streamlined through quick-disconnect cables, and a single power drop fed the main control enclosure, eliminating the need for extensive onsite wiring.

|

Integration with the automated roll-up door was a critical requirement. The system was programmed so that pallets would stop in Zone-2 and send a "pallet present" signal to the door controller. Once the door was raised, the conveyor received a "Run" input, allowing the pallet to advance to Zone-3. This ensured smooth and secure transitions between the cage and the warehouse.

Operator interaction was designed to be simple and intuitive. Ultrasonic sensors at the infeed and discharge points detected forklift presence, halting conveyor movement during loading and unloading to prevent accidents. This feature greatly enhanced safety by eliminating the risk of full pallets moving while engaged by a forklift.

The result was a robust, user-friendly system that improved operational efficiency and safety. Accumulation zones reduced unnecessary forklift movements, minimizing hazards and optimizing workflow. Alba’s plug-and-play MZPA control system delivered a cost-effective solution that required minimal onsite integration while providing long-term reliability.

Alba Manufacturing continues to be a trusted partner for pallet handling applications, offering durable, efficient, and easy-to-install solutions. For more information or to locate your nearest Alba Partner Network member, call 866.252.2634 or visit our website at www.albamfg.com.

Conveyor/Product Specifications |

| • |

Product: 40" x 48" Wood GMA Pallets, 2,000 lb. Maximum Weight |

| • |

Length: 29’10” Long Line Consisting of Six (6) Zones @ 4' 11-1/4" Overall with a 2-1/2" Wide Door Gap |

| • |

Rollers: |

| |

- |

2-1/2" Diameter x 11 Gauge Wall, 11/16" Hex Axles, Spring Retained, #40A21 Sprockets, Grease Packed Ball Bearings |

| |

- |

On 3-1/4" Roller Centers |

| • |

Effective Width: 52" Effective Conveying Surface |

| • |

Motor: |

| |

- |

1/2 HP, Baldor C-Frame Motor and Dodge Tigear II Gear Reducer, 230/460/3/60, RC-40 Drive Chain, Under Slung Mounted Drive |

| |

- |

Speed: 30 FPM, Fixed |

| • |

Elevation: 11" Top of Roller |

| • |

Paint: Alba Blue with Safety Yellow Chain Guards |

| • |

Standard Items included: |

| |

| - |

End Stop: Fixed Channel End Stops with Fork Cutouts |

|

|