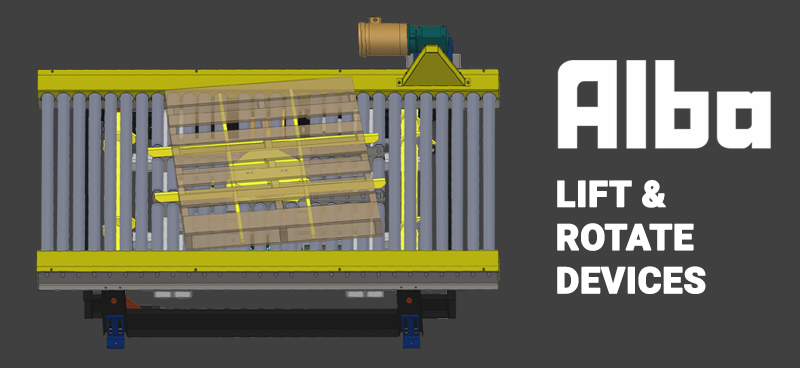

Behind the Rollers – Alba's Lift & Rotate Device |

|

Alba's Lift & Rotate unit is a valuable component of a pallet handling conveyor system when you need to rotate a pallet while maintaining its original direction of travel. This functionality is essential in situations where the leading edge of a pallet needs to change, but the overall direction of the pallet's movement cannot be altered. It is also useful when operators or robots need access to all four quadrants of a pallet.

These Lift & Rotate units typically come with an integrated Chain Driven Live Roller (CDLR) conveyor. However, in some cases, drag chain conveyors can be used in different configurations depending on specific requirements. In this newsletter, we'll go BEHIND the ROLLERS, focusing on lift and rotate applications that predominantly use roller conveyors and explore the inner workings of Alba's Lift & Rotate conveyor system.

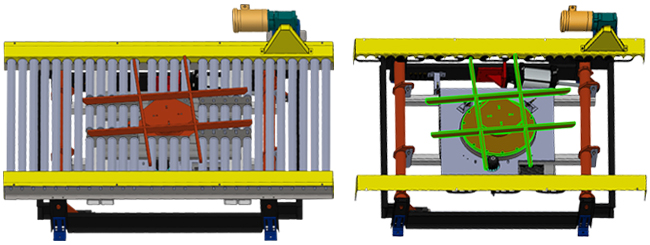

The standard lift and rotate design allows rollers to be driven the entire length of the conveyor, providing positive drive to the pallet until it traverses the rotational zone. Similar to turntables, the rotation of the Lift & Rotate conveyor can be split into two main subgroups based on the application. The two methods of rotation are either a 1-HP electric brake motor or a pneumatic cylinder.

Like turntables, the pneumatic version is constrained to a 90° rotation before reversing direction and then returning to the home position. The electric version allows for continuous rotation since no devices or wires extend to the top of the lifting weldment; hence, no slip ring is needed for wire routing.

There are two primary methods to turn (rotate) a pallet. A turntable (discussed in previous articles) will rotate the pallet and change the pallet’s direction of travel on the conveyor, but maintains the pallet’s leading edge. A 90° chain transfer will change the pallet’s direction of travel and the pallet’s leading edge. The Lift & Rotate, on the other hand, will also turn the pallet but maintain the direction of travel on the conveyor. Therefore, it can take a 40” x 48” pallet and change the leading edge from the 40” edge to the 48” edge leading without changing the direction of travel.

Another advantage of the Lift & Rotate unit is that it can rotate the pallet using a smaller footprint as compared to a turntable or transfer. Why change the leading edge? Two examples: changing the leading edge is important in pallet strapping applications where adding a cross-strap is necessary to secure a load; or when unloading a pallet and either the pallet pockets are in the wrong orientation or the pallet needs to be picked up from the side or end of the conveyor and orientation needs to remain the same relative to the conveyor.

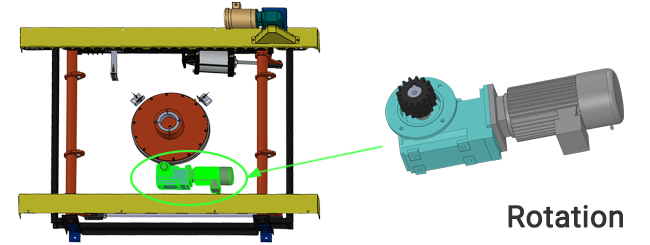

Rotation |

|

A Lift & Rotate unit with electric rotation uses a VFD-rated gearmotor with a brake, which when coupled with a customer supplied control system, allows the rotation to be much more controllable for soft starts and stops.

Similar to the turntable, the Lift & Rotate unit uses a heavy-duty slewing bearing, typically seen in heavy duty equipment (i.e., contruction equipment). This slewing bearing has a grease manifold and is pre-piped allowing grease to be applied to the bearing for easy maintenance from a common point at the edge of the turntable base. The pneumatic rotation version (not shown) of the lift and rotate uses a rotational cylinder to rotate the pallet 90° in one direction then reverse direction and rotate the pallet 90° in the opposite direction.

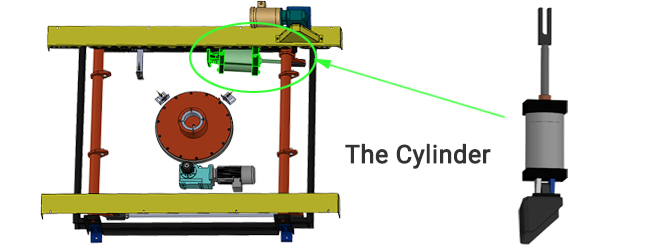

The Cylinder |

|

Providing the lift for the Lift & Rotate unit, the pneumatic cylinder must provide enough capacity to raise even the heaviest load. The cylinder is mounted to the lift and rotate base with the cylinder’s rod end mounted to a clevis on the pivoting arms similar to Alba's transfer design.

In conclusion, Alba's Lift & Rotate unit offers a highly adaptable and valuable solution for pallet handling conveyor systems, particularly when precise pallet rotation is needed without altering the direction of travel. This innovative component seamlessly integrates into conveyor systems, enabling the safe and efficient repositioning of pallets for various applications.

For additional information on our lift and rotate units and other pallet handling equipment, reach out to our Sales Team today! For rock-solid solutions and conveyor systems, contact Alba Manufacturing today via email at rocksolidconveyor@albamfg.com, telephone at 866.252.2634 or visit our website at www.albamfg.com to discuss. |