|

Alba Manufacturing has developed a highly efficient and user-friendly system for steel rack handling using our standard plug-and-play MZPA Accumulation Controls System. This system integrates heavy-duty CDLR Conveyors and a Frame-to-Frame Transfer, ensuring seamless movement and accumulation of 1,150 lb. steel racks while minimizing the complexity of controls integration, wiring, and installation. The end user is a parts supplier for multiple car manufacturers.

|

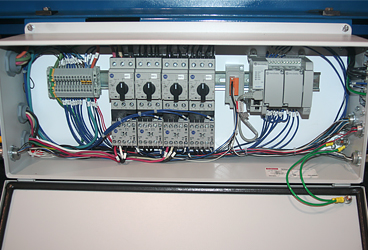

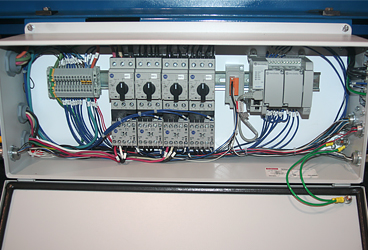

A key challenge for the end user was the need for a cost-effective yet robust controls solution that required minimal onsite integration. Alba addressed this by implementing a straightforward accumulation program utilizing our standard MZPA controls which include an Allen Bradley PLC, and commercially available easily sourced electrical components. The pre-mounted controls are designed for quick installation with all the wiring streamlined through quick disconnect cables. A single power drop feeds the main panel with power daisy-chained to all 480V motors, eliminating the need for complex onsite wiring or conduit runs.

|

|

|

Operator interface played a crucial role in the design of this system, emphasizing simplicity and reliability. Ultrasonic sensors at the rack infeed and discharge points detect the presence of a forklift, allowing the system to halt movement in the affected zones during the loading and unloading of racks. This feature eliminates the risk of racks conveying while being engaged by a forklift. At the product loading position, operators interface with the controls system with a basic push-button control box mounted on a floor stanchion. This control interface provides essential functions, including a call button, a send button, an emergency stop button, and an emergency stop reset, ensuring that operations remain straightforward and efficient.

The durability of Alba’s conveyor components was also a major focus. To withstand the rigorous demands of steel rack handling, the roller tube wall thickness was increased from the standard 11-gauge to a more robust 7-gauge. Additionally, upgraded ABEC-1 “PFR” series precision bearings were incorporated to handle the stress imposed by the steel rack’s rigid and sometimes warped steel bottom runners traveling over the rollers. For added resilience, the chain transfer system was designed with a flat sidebar chain rather than the conventional roller chain, providing a more stable conveying surface for steel racks.

|

By implementing this advanced yet easy-to-use system, Alba significantly enhanced the customer’s operational efficiency and safety. The accumulation of racks before and after the loading positions reduced the need for excessive forklift movements, minimizing potential hazards while optimizing workflow. Operators were able to complete their tasks with minimal effort, reducing unnecessary handling and movement of products. Alba’s plug-and-play MZPA Accumulation Controls System has proven to be an ideal solution for the customer, delivering durability, efficiency, and seamless integration with minimal disruption to existing operations.

Alba Manufacturing is your full-service conveyor manufacturer for all your pallet handling applications. Call us to locate your nearest Alba Partner Network Member to assist with your next project at 866.252.2634 or visit our website at www.albamfg.com.

Conveyor/Product Specifications |

| • |

Length: 5'0" Overall Zone Length |

| • |

Rollers: |

| |

- |

2-9/16" Diameter x 7 Gauge Wall, 11/16" Hex Axles, Spring Retained, #40A21 Sprockets, ABEC-1 "PFR" Series Grease Packed Ball Bearings |

| |

- |

On 4" Centers |

| • |

Effective Width: 52" Effective Conveying Surface |

| • |

Motor: |

| |

- |

1/2 HP, Baldor C-Frame Motor and Dodge Tigear II Gear Reducer, 230/460/3/60, RC-40 Drive Chain, Under Slung Mounted Drive |

| |

- |

Speed: 30 FPM, Fixed |

| • |

Elevation: 17" Top of Roller |

| • |

Paint: Cream Color with Safety Yellow Chain Guards |

| • |

Standard Items included: |

| |

| - |

End Stop: Unit includes a 116" Long Fixed Channel End Stop, Common to Both of the Transfer’s CDLR Conveyors |

| - |

Back Stop: One (1) CDLR Conveyor includes a 5'2" Long Back Stop Mounted to the Top of the Scalloped Chain Guard |

|

Value Added Features |

| • |

Two (2) Conveyors include a Floor Mounted Fork Truck Wheel Stop x 5'0" Long Painted Safety Yellow |

| • |

Alba's Standard MZPA Zero Pressure Accumulation Control Package |

| • |

A Push Button Control Box Mounted to a 36" Tall Floor Mounted Stanchion |

| • |

Ultra Sonic Sensors Mounted to Conveyor Frame at the Fork Truck Load and Unload Zones |

| • |

E-Stop Circuit with a Mushroom Style (Push/Pull) E-Stop Push Button located on the Control Box with two (2) Pull Cord E-Stop Switches along Conveyors Frame |

|