This month’s story features a market leader and manufacturer of feminine, adult, infant and household care items. Products may range from diapers, disposable wipes, and adult incontinence to household paper products.

As a diverse manufacturer with an extensive distribution system, the end user needed a way to handle its various products within the same conveyor system, regardless of pallet type, substrates, or product sizes.

The easiest solution – create a high quality, reliable full and empty board conveyor system to deliver full pallets (on system boards) to a fork truck offload point (upper level). Once the pallet is removed by the forklift operator, the system returns the empty boards on a lower-level conveyor for final delivery to a board stacker at the beginning of the system for recirculation.

About the Application

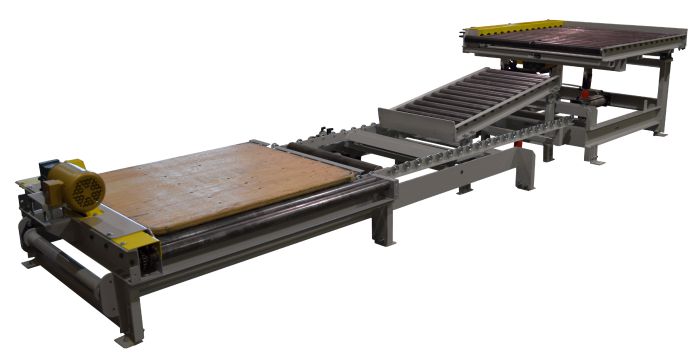

In partnership with a systems integrator, Alba developed a system that included a high level CDLR (Chain Driven Live Roller) Conveyor for the outbound, fully loaded pallets being conveyed on system boards.

- Full pallets weighed 2,600 lbs.

- Empty wooden system board weighed 50 lbs.

- Board dimensions: 52” wide and 44” long x 1-1/4” thick wood

- Alba used the standard, pre-engineered Model #251160-4.5 CDLR Conveyor for the 16 (sixteen) high level conveyor lanes which ran 54’ long

- A Model #251140-6 CDLR Conveyor was used for the “Tip-Down” section at the end of each of these lanes where the fork truck would unload the pallets

- The robust Tip-Down Conveyor was 5’ long and built to take fork lift abuse

How It Works

A Tip-Down, over-center toggling mechanism remains rigid in the raised or tilted position.

When the Tip-Down is tilted, the conveyor reverse drives the empty system board down the decline allowing it to gravitate and deposit on an adjacent gravity conveyor with a fixed end stop.

The declining system board motion is regulated by a speed control braking roller.

The Tip-Down raises back up to the “level” position allowing another full pallet to convey into the fork truck unload position.

Meanwhile, the empty system board rests underneath the main line on a lower level, decline gravity conveyor. It waits to be transferred to the main line, an empty system board return conveyor.

When the main line 2-strand 90° skate wheel transfer is clear, this transfer raises and pivots two strands of skate wheel rails past the height of the gravity decline conveyor which lifts the empty board off the gravity and allows it to decline down the skate wheels transferring it onto the transfer conveyor itself in-line with the main line powered return conveyor. The speed and decline of the system board is controlled with a speed control braking roller so the system board has a nice, smooth, controlled motion – until it stops at the guide rail bumper of the return line CDLR Conveyor.

The skate wheel rails retract and the system board is now completely on the main line ready to convey downstream and recirculate back to the beginning of the system and repeat the production journey again.

Video: Pallet Unload Empty and Board Return Video

Review our latest video to learn more about our Pallet Unload & Empty Board Return System.

Empty System Board Return Conveyors

Tip Down CDLR Conveyor

Alba Manufacturing is your full-service, turnkey systems provider for your conveyor application needs. Call us to locate your nearest Alba Partner Network Member to assist with your next project at 866.252.2634 or visit our website at www.albamfg.com