When it comes to conveyor systems, one size definitely does not fit all—especially when you consider the wide range of indoor climate conditions found in manufacturing and material handling environments. At Alba Manufacturing, we understand that the success of a conveyor system isn’t determined solely by its strength or speed, but also by how well it performs in the specific environment where it operates. That’s why we take climate into serious consideration during every phase of conveyor design and selection.

Temperature variation is one of the most common challenges. While some facilities maintain a consistent climate, others deal with wide fluctuations due to open dock doors, seasonal shifts, or production-related heat. Cold storage areas and refrigerated spaces call for conveyors that can operate efficiently in low temperatures without lubricant failure or material brittleness. On the other end of the spectrum, high-heat areas like foundries or ovens demand systems made from heat-resistant materials that won’t warp, expand, or seize under stress.

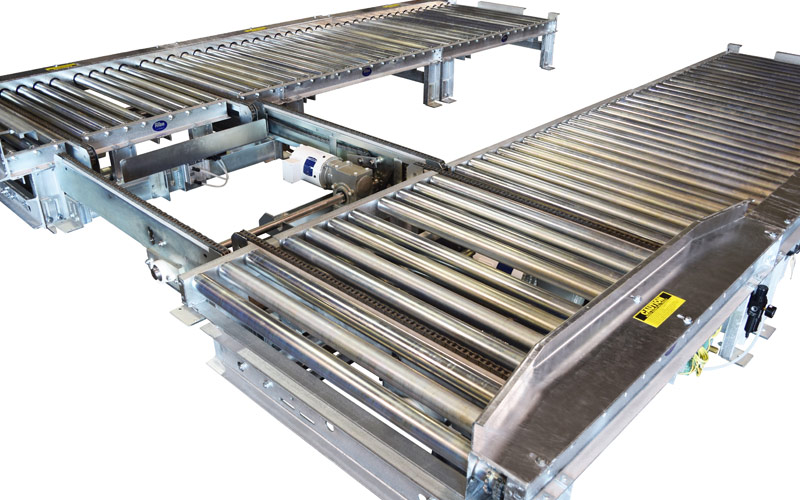

Conveyor in a Cold Environment

Humidity and moisture are also critical factors. Whether from cleaning protocols, condensation, or humid environments, excess moisture can degrade equipment over time. Alba addresses this with corrosion-resistant finishes, sealed components, and drainage-friendly designs—solutions that keep systems running even when moisture is unavoidable.

Dust and airborne particulates pose another serious threat. In industries like woodworking, textiles, or bulk powder processing, fine particles can infiltrate bearings, motors, and rollers, causing excessive wear and eventual breakdowns. Alba designs conveyors with dust-resistant housings and protective enclosures that safeguard vital components, extending system life and reducing maintenance needs.

In some facilities, chemical exposure is a concern—particularly in food processing, pharmaceuticals, or sanitation-intensive operations. Harsh cleaners, solvents, and sanitizing agents can compromise traditional materials and coatings. Alba combats this with chemical-resistant finishes, stainless steel construction, and FDA-compliant materials that hold up under rigorous cleaning cycles.

Even airflow and ventilation, often overlooked, can impact conveyor performance. Facilities with large HVAC systems, pressurized zones, or inconsistent airflow may see unexpected effects on electronics, thermal expansion, or mechanical function. Alba’s engineers factor in these environmental elements during system design, ensuring stable performance regardless of ambient conditions.

Conveyor Used in Food Processing

Ultimately, indoor climate conditions influence every detail of conveyor performance—from the materials used in construction to the type of lubrication in the bearings. That’s why Alba Manufacturing doesn’t just deliver conveyors—we provide fully engineered solutions designed to perform in your specific operating environment.

Whether you’re running a high-speed packaging line, a cold storage warehouse, or a facility exposed to dust and chemicals, Alba offers a full range of heavy-duty solutions. Our Chain Driven Live Roller (CDLR) Conveyors, Drag Chain Conveyors, Gravity Roller systems, and Motorized Zero Pressure Accumulation (MZPA) Conveyors are all designed with real-world challenges in mind. We also offer Pallet Stackers, Turntables, and accessories that integrate seamlessly into your operation.

For conveyor systems that are as rugged as they are climate-ready, trust the experts at Alba Manufacturing. Visit www.albamfg.com to learn more or to talk to our team about your specific application needs.