In the fast-paced world of manufacturing and warehouse distribution, facility layout and design play a pivotal role in ensuring smooth operations and maximizing productivity. With the ever-present need for adaptation and expansion, businesses often face challenges in finding the perfect balance between pedestrian and forklift traffic.

Alba Manufacturing leveraged its extensive industry expertise to deliver a tailored solution to a Fortune 150 end user, optimizing warehouse operations through strategic layout design and the integration of a swing gate system.

The Problem

To create an efficient facility layout, Alba Manufacturing considered several key factors:

- Ease of future expansion or change: Alba Manufacturing recognized the importance of designing a layout that could easily accommodate future growth and changes in production requirements.

- Flow of movement: The smooth flow of materials, equipment, and personnel is critical to optimize efficiency. Alba Manufacturing prioritized creating a layout that minimized bottlenecks and allowed for seamless movement throughout the facility.

- Material handling: Efficient material handling is essential for minimizing downtime and maximizing productivity. Alba Manufacturing aimed to design a layout that facilitated smooth and streamlined material flow.

- Output needs: Understanding the end user’s specific output requirements allowed Alba Manufacturing to tailor the layout, accordingly, ensuring that productivity goals were met.

- Space utilization: Maximizing space utilization is crucial for efficient warehouse operations. Alba Manufacturing strived to create a layout that made the best use of available space, optimizing storage areas and workstations.

- Ease of communication/support: Effective communication and support systems are vital for maintaining a cohesive and productive work environment. Alba Manufacturing focused on designing a layout that facilitated clear communication and provided adequate support infrastructure.

- Safety: Ensuring the safety of all personnel and equipment is a top priority in any facility. Alba Manufacturing incorporated safety considerations into the layout design, implementing measures to minimize risks and accidents.

The Challenge

The end user faced a challenge with their existing pallet conveyor layout, which conflicted with forklift travel and access. This conflict necessitated a solution that would allow for the occasional travel of forklifts across the conveyor path while maintaining pedestrian safety and operational efficiency.

The Solution

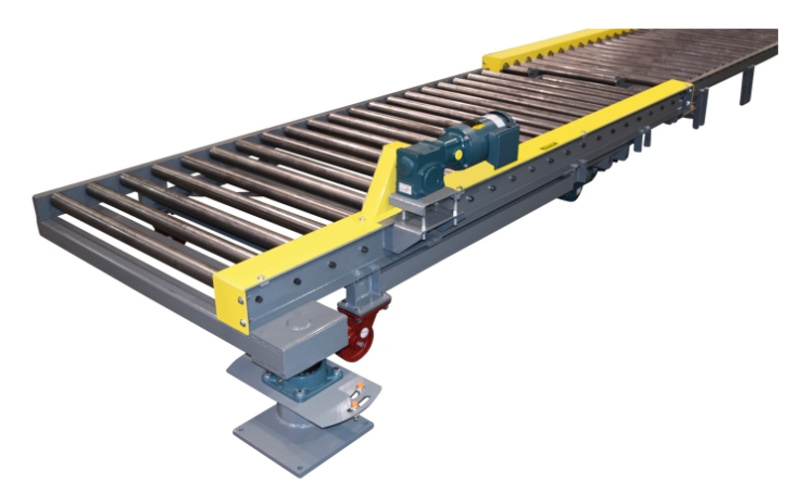

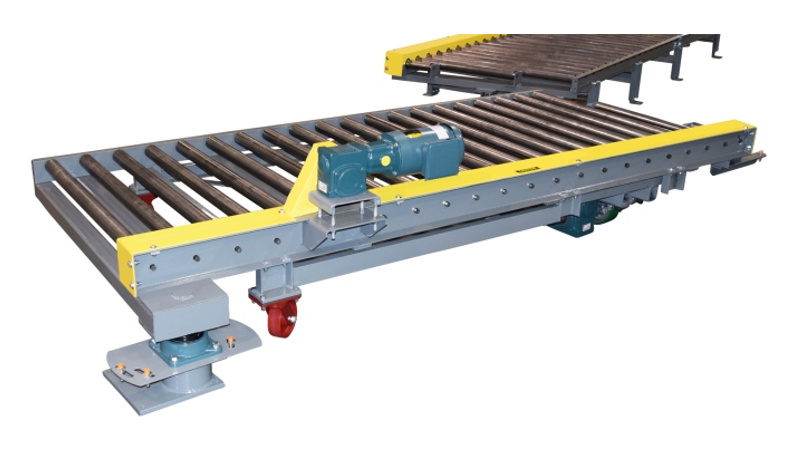

Alba Manufacturing proposed the installation of a swing gate as a solution to the challenge. Incorporating a swing gate into the layout, the end user could maintain a high rate of pallet movement, approximately 45-50 pallets per hour, while allowing for occasional forklift travel across the conveyor path.

The implementation of the Alba Manufacturing swing gate brought several notable benefits to the facility:

- Enhanced productivity: The swing gate allowed for uninterrupted pallet movement, ensuring a high throughput rate of pallets while minimizing disruptions caused by forklift travel.

- Operator safety and efficiency: The automated gate travel feature eliminated the need for operators to leave the forklift, reducing downtime and enhancing overall efficiency. Furthermore, the gate’s safety locking pin and proximity sensors provided controllable, dependable, and safe operation.

- Space optimization: The swing gate design allowed for efficient space utilization by minimizing the footprint required for gate operation. This optimization of space allocation contributed to a more streamlined layout overall.

Efficient facility layout and design are crucial components of successful manufacturing and warehouse distribution operations. Alba Manufacturing’s partnership with the Fortune 150 end user exemplifies how a well-designed layout and the implementation of a swing gate can optimize warehouse processes, enhance productivity, improve safety, and maximize space utilization.

When faced with similar challenges, businesses can rely on experienced industry partners like Alba Manufacturing to provide innovative solutions and valuable insights, ensuring the smooth and efficient functioning of their facilities.

The success of this facility’s transformation highlights the importance of collaborating with experienced partners like Alba Manufacturing. With over 50 years of industry expertise, Alba Manufacturing understood the specific challenges faced by the end user and leveraged their knowledge to devise a tailored solution.