Problem

The end user’s product source comes from several different manufacturing lines that are located throughout the plant. In order to move the product to the shipping area, it was necessary to transport the pallets via fork truck. Numerous fork trucks were utilized to transport the product from multiple packaging lines to the shipping and receiving area – not an ideal situation due to the congestion, high traffic intersections and potential hazards to workers. The customer wanted to reduce the fork truck traffic and still be able to transport the product to the loading docks from the same existing production lines.

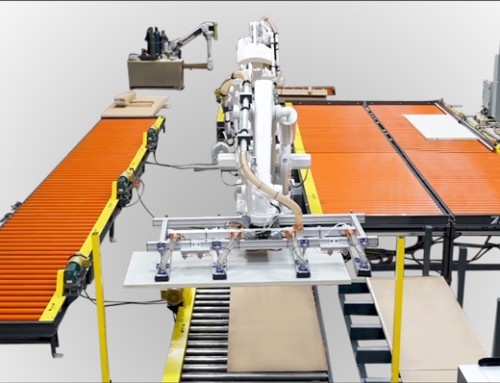

Solution

We worked with our partner’s team to come up with the solution necessary to bring the lines together to a pair of common truck lines that lead to the designated shipping area. After the fully-loaded pallets arrive at the end of the line, the pallet is picked up by a fork truck and loaded into semi-trucks for delivery to the distribution warehouse or retail outlet.

Results

- Install over 1,000 linear feet of conveyor, which included elevation changes and directional changes;

- Allow access for maintenance to service the packaging equipment;

- Reduce safety hazards due to excessive fork truck traffic; and

- Reduce the number of fork trucks and truck operators which allowed the workforce talent to be reallocated and utilized in other areas of the facility.

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.