Product: 12″ – 48″ x 36″ – 120″ Long Stacks of Wooden

Doors, Maximum Weight Per Stack of Doors 4,400 lb.,

Single Doors Maximum Weight of 440 lb.

7robotics, an APN (Alba Partner Network) system integrator, headquartered in Roseburg, Oregon, specializes in creating innovative solutions harnessing the power, speed, and safety of robotics. Their unique name is derived from three things: there are seven axes to a robot, number seven in the bible (appearing over 700 times) symbolizing completion or perfection, and lucky number seven.

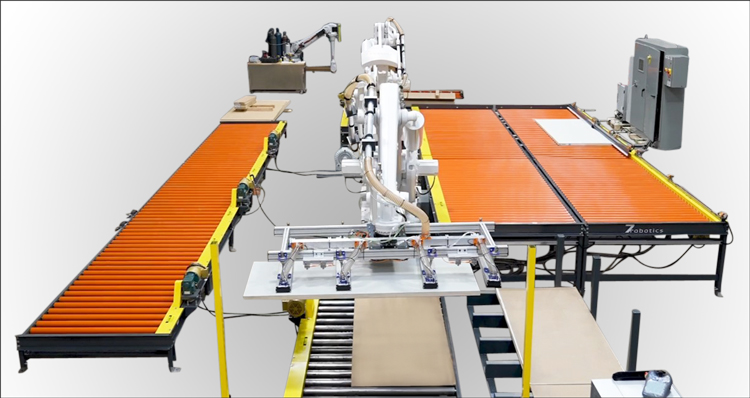

7robotics specializes in handling products made from wood such as doors, plywood, and veneers. They provide a total system solution, including robots, conveyor, and automation controls. Their latest venture took them into the world of custom door manufacturing, an industry that demands precision, speed, and adaptability.

The Challenge

The challenge at hand was to create a turnkey solution for handling both single doors and stacks of wooden doors. The end user in the custom door industry had specific requirements: the solution had to meet stringent speed standards, and it had to integrate seamlessly with an edge-bander. Moreover, there was a wide array of door sizes to consider, making the project even more complex.

Initially, the end user had sought a solution from the supplier of the edge-bander. However, they were confronted with a significant issue – the price was high, and the lead time was long. It was at this crucial juncture that 7robotics stepped in. Their expertise and reputation for finding unique solutions made them the perfect fit for the project. The customer’s demand for speed was a challenge, but 7robotics was determined to meet it.

The Solution

To make their vision a reality, 7robotics recognized the need for a robust and adaptable conveyor system that could handle the diverse range of doors, from single units to massive stacks, without causing any damage. They turned to Alba Manufacturing for help.

Alba Manufacturing rose to the occasion and worked closely with 7robotics to design a tailor-made solution. The heart of this system was a series of Chain Driven Live Roller (CDLR) conveyors. What made these conveyors stand out was the 1/8″ thick Kastalon coating on their tubes. This coating provided a cushioning layer that protected the doors from any potential damage as they were transported from one workstation to another. Additionally, Alba also supplied three CDLR conveyors without Kastalon to suit different requirements.

The real game-changer in this solution was the frame-to-frame transfers provided by Alba. Two variants were supplied – one with seven v-belts and the other with three v-belts. These transfers ensured that the doors were not just transported efficiently but also aligned perfectly for integration with the edge-bander.

To make life easier for 7robotics, Alba shipped all these components fully assembled. This standard Alba procedure expedited the setup of the robotic cell for testing, allowing 7robotics to focus on fine-tuning their innovative solution.

The Result

In the end, 7robotics was able to deliver a turnkey automatic feeding and stacking system, in part, due to Alba’s heavy-duty conveyor system. The solution could handle the significant weight of stacked doors, ensuring that operations ran efficiently and safely. The Kastalon-coated CDLR rollers guaranteed that no doors were harmed in transit, even while accommodating the vast range of sizes.

The frame-to-frame transfers were instrumental in aligning the doors precisely for integration with the edge-bander, making it possible to meet the customer’s speed requirements.

Together, Alba Manufacturing and 7robotics turned a challenging problem into a success story. The custom door industry has a new and innovative solution that can handle their diverse needs, and the end user has a complete, seamless, and efficient process for their operations. In the heart of Roseburg, Oregon, the collaboration between 7robotics and Alba Manufacturing stands as a testament to the power of ingenuity, innovation, and a shared commitment to solving complex problems.

Conveyor/Product Specifications

- CDLR Conveyor: Alba supplied Eleven (11) CDLR Conveyors, Model 251160-6, Two (2) 11′-0″ long, Six (6) 11′-6″ long, and Three (3) 12′-0″ long.

- Frame-to-Frame Transfers: Alba supplied Two (2) Transfers with V-Belts. One Transfer had 7 Strands of V-Belts spaced on 6″ & 12″ centers, and the other Transfer had 3 Strands of V-Belts on 12″ & 18″ centers.

- Rollers: 2-1/2″ x 11 Gauge, on 6″ centers

- Effective width: 52″ on 9 CDLR Conveyors & 60-1/2″ on 2 CDLR Conveyors and the 2 Frame-to-Frame Transfers.

- Motor: 1/2 & 1 HP Baldor Super E Motors

- Elevation: 15″ & 37-1/2″ Top of Roller

- Paint: RAL 7016 (Anthracite Grey) Color Match

- Standard Items Included: Fixed End Stops and Adjustable Back Stop

Value Added Features

1/8″ Kastalon Coated Rollers, Adjustable Back Stop with a UHMW Face to protect the doors from damage.

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.