Don’t put your gas grill away just because cooler weather is on the horizon! It’s time to cook up some of your favorite meats and eats. Got your turkey fryer ready because Thanksgiving is right around the corner. Increasingly more and more Americans are consuming meat and this consumption is fueling the growth of the frozen meat market. The global frozen meat market was valued at $22.18 billion in 2018 and is projected to grow by 4.9% by 2027.1 There has been a steady rise in income in the U.S. which has caused a change in lifestyle. This change in lifestyle is facilitating growth in the U.S. frozen food market.2

The Backstory

This case study features a conveyor system for automatic palletizing of frozen meat that has come from a flash freezer. This meat was first frozen, then palletized, then sent back to a frozen warehouse on site. The current means of processing the meat was to hand palletize and then send it to a third-party logistics facility for flash freezing and storage.

There was a real need for reducing the transportation time and effort by having the processing, freezing, palletizing, and storage all in one facility.

The Application

Our Alba integration partner, Adaptec Solutions, reached out to Alba to provide an automatic way to dispense pallets to multiple lanes of palletizing utilizing two (2) robots. They also needed a means of conveying the fully palletized pallets downstream to be wrapped and finally sent to the frozen warehouse. They needed a line of conveyors that could dispense a pallet, add a slip sheet and then transport that pallet to one of eight lanes of conveyor that are palletized by a set of robots. This conveyor needed to work within their robotic cell and transport downstream for wrapping and then ultimately be sent back to the freezer.

The Solution

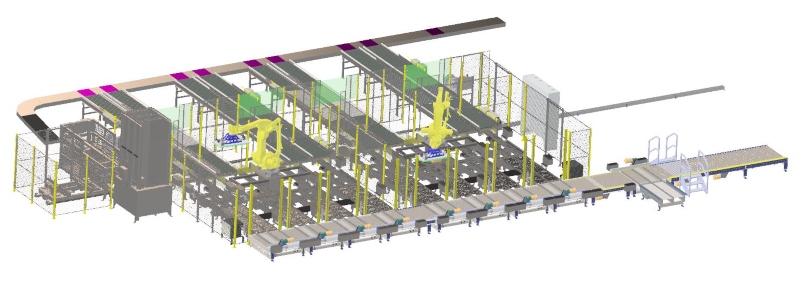

Alba provided a transfer car that could take the empty pallet from the pallet dispenser through a slip sheet dispenser and ultimately downstream to multiple lanes of a robotic palletizing area. Alba provided a series of Drag Chain Conveyors which transported the empty pallets to the robots to palletize product. Alba also provided several pop-up chain transfers and CDLR (Chain Driven Live Roller) conveyors that moved the pallets through the cell to be wrapped and then picked up by fork truck for further processing.

Alba worked with our customer to design a system that was versatile and could meet the rates and throughputs that were necessary. Alba provided drawings in 3D Solidworks files to our client so they could check clearances and fits on this extremely tight system.

Conveyor/Product Specifications

- Dual Drag Chain Top T-Car with Galvanized Rails

- (1) Pallet Dispenser (controls by customer) but with all Devices pre-wired to Junction Box

- (1) Slip Sheet Dispenser (controls by customer) but with all Devices pre-wired to a Junction Box

- Various 2-Strand and 3-Strand Drag Chain Conveyors (some with tread plates for maintenance cross overs)

- Various 3-Strand Pop-Up Chain Transfers

- (6) 5′-0″ Long Chain Driven Live Roller (CDLR) Conveyors

- (8) Pop-Up Pneumatic Pin Stops @ “build zone” included Double Solenoid, Proximity & Cable

- Rollers: 2-1/2″ Diameter x 11 Gauge with 11/16″ Hex Axles

- Effective Width: 52″

- Elevation: 18″ Top of Roller

- Paint: Color matched to customer RAL Gray Color

- Super “E” VFD-Rated Motors

- Under Slung Drives

- Speed: 60 FPM @ 60Hz

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.