Problem

A systems integrator needed to convey and strap pallets in both directions within the application. The end user’s 48” x 48” flexible pallet transported stacks of empty buckets. The pallets weighed 500 pounds.

Solution

Through a partner systems integrator, Alba’s engineering team obtained a sample pallet from the end user to inspect its overall construction and design. Some conveyor manufacturers would consider this a “special” application resulting in a long lead time with an exorbitant price tag. Not the case with Alba’s pre-engineered, building block style modules. After a thorough inspection, the engineering team designed a system to handle the pallets safely and effectively.

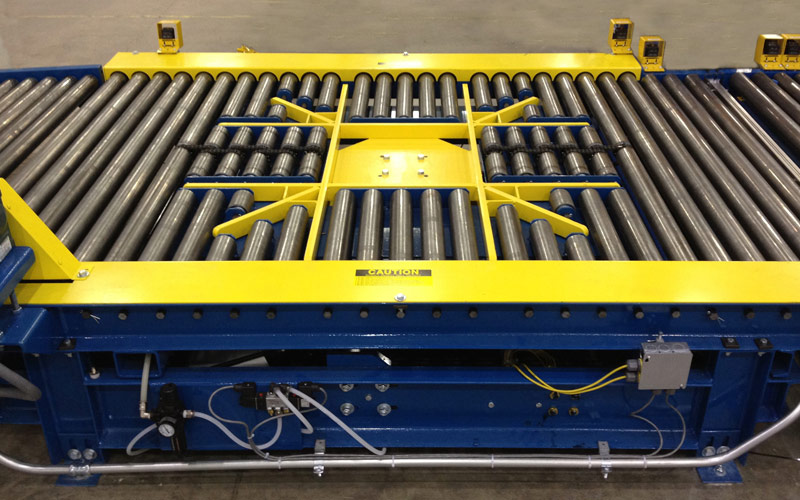

The application required our pre-engineered Chain Driven Live Roller Conveyor (CDLR Model 251140-3.25) and our Lift and Rotate Module (Model 251140-3.25). The 3.25 inch roller centers allowed the stacks of empty buckets to convey smoothly while maintaining proper pallet orientation. The lifting mechanism was modified to include members at a 45 degree angle to support the flexible pallet.

Results

The unit was manufactured, thoroughly inspected & tested, and shipped fully assembled. After a simple installation, both the systems integrator and end user were extremely pleased with system’s design and performance.

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.