This application involved menu display boards. Alba’s network partner designed an integrated system for a manufacturer who supplies menu boards to one of the top 20 restaurant chains in the United States.

Problem

Prior to the new system installation, the process was completely manual with only one or two signs produced at a time.

Solution

Alba provided a part of the integrated system which contributed to increased production and safety while reducing employee work strain.

Result

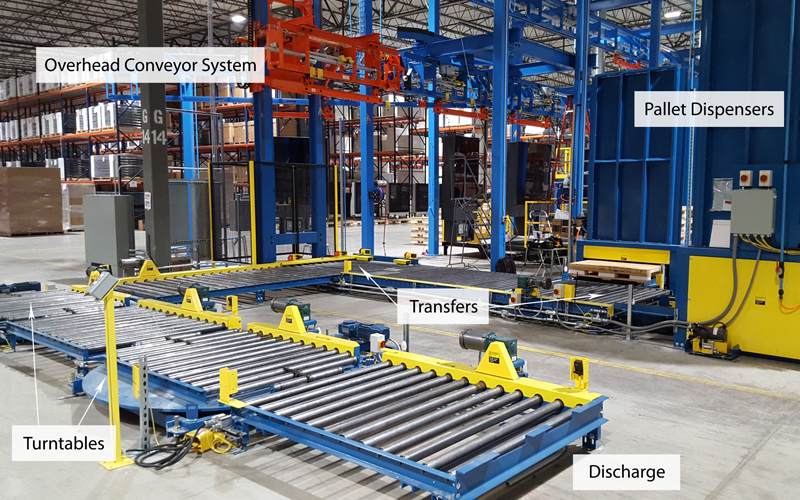

The wood pallets come in two sizes: 64” x 48” and 48” x 48”. The pallets are introduced empty by two different pallet dispensers. Once the display boards are completely assembled and stacked, the finished pallets weigh 2,000 lbs.

This system was designed to present the fronts and backs of the display boards to the empty pallets via an overhead conveyor system already in place.

Once presented, the display boards are gathered, rotated, and pieced together by a worker to form a complete board. For safety, the worker is only allowed to be on one side of the conveyor.

The assembly process was carried out by using Alba Chain Driven Live Roller (CDLR) Conveyor (2-1/2” diameter x 11-gauge rollers on 6” centers) and transporting them to Alba’s low-profile turntables. These turntables are 84” in diameter with a 52” effective width utilizing CDLR conveyor with the 2-1/2” diameter x 11-gauge rollers on 6” centers mounted on each turntable. To maintain proper pallet orientation prior to the turntable, Alba Thru-Frame-Transfers (TFT) were incorporated within the system as well.

Upon completion, the assembled units are picked-up at the discharge end via fork truck.

About Us

Alba Manufacturing, established in 1973, engineers and designs heavy-duty roller conveyor systems. Our systems consist of chain driven live roller (CDLR), zero pressure accumulation, drag chain, gravity, lift and rotate, pallet stackers and dispensers, turntables, chain transfers and transfer cars. Our corporate office and manufacturing facility is located in Fairfield, Ohio, approximately 30 minutes north of Cincinnati, Ohio.

For more information regarding this application/solution, please contact us via phone at 866.252.2634; via web at www.albamfg.com or via email at RockSolidConveyor@albamfg.com.